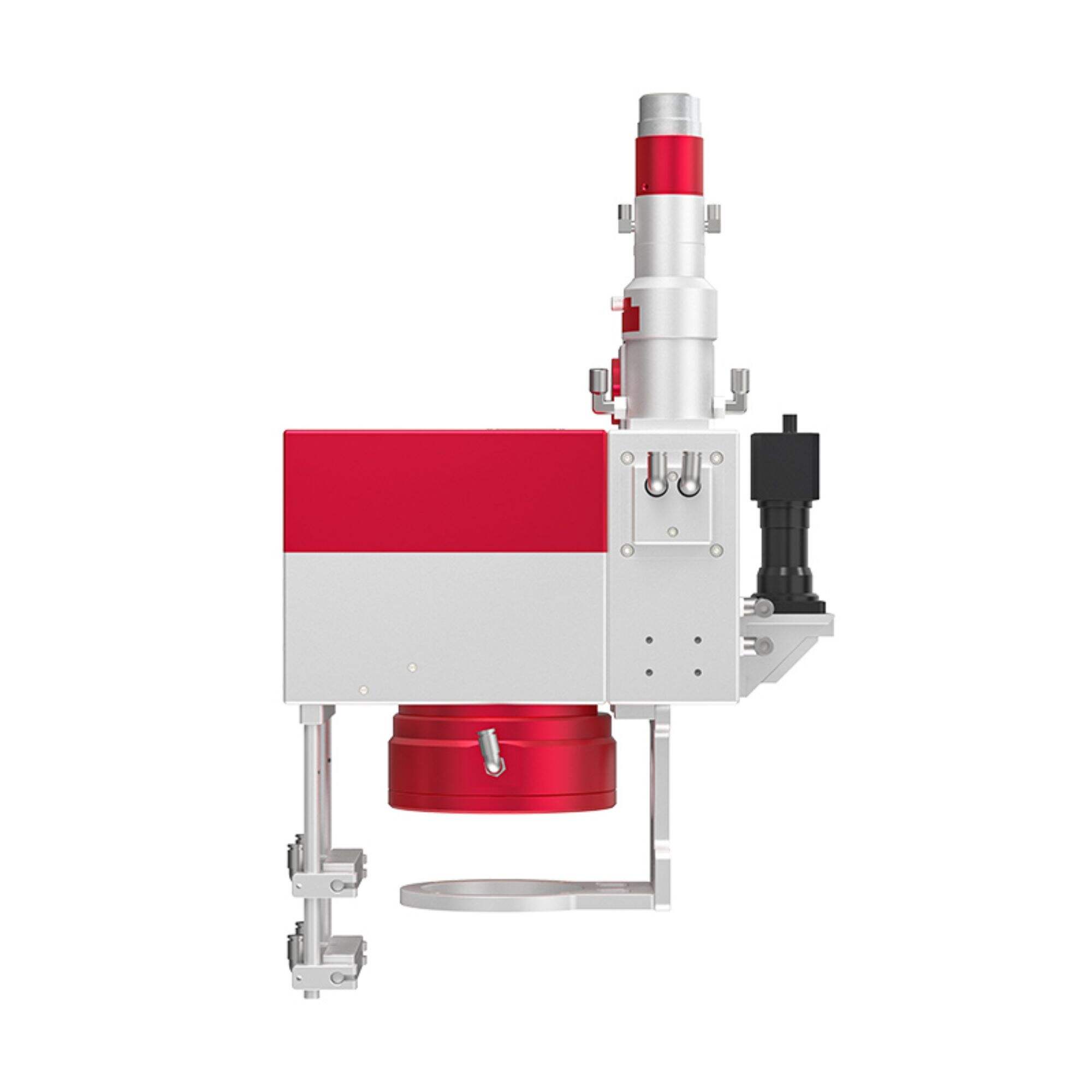

The 2D composite welding galvo scanner supports two laser inputs of different wavelengths at the same time, which can replace the ring laser welding scheme and apply to the scene requiring higher welding quality. It has the advantages of low program cost, small flight measurement and high welding quality.

Product advantages

● Low spatter

Two laser input, one as a preheating laser, the other as a welding laser, can replace the ring spot output laser program, welding splash is small.

● High quality

Double optical path composite welding has the advantages of good welding effect and high quality.

● High power

Specially customized high-power optical lens components, combined with efficient water-cooling structure and multistage temperature protection, can withstand pulsed laser power up to 6000W.

● High efficiency

High speed and high power water cooled motor and high speed driver, as well as efficient water cooled field mirror, fast cleaning speed, high efficiency, good stability.

Product Parameters | |

Support wavelength |

1030nm-1090nm |

Support wavelength |

915nm |

Galvo scanner incident spot |

30mm |

Scanning angle |

+0.35rad |

Linearity |

>99.9% |

Tracking time |

0.55ms |

Marking speed |

<4000mm/s |

Positioning speed |

<15000mm/ |

Maximum withstand power (1064nm) |

6000W |

Maximum withstand power (915nm) |

2000W |

Repetitive positioning accuracy (RMS) |

<2urad |

Long axis drift (after 30 minutes of preheating) |

<0. 1mrad |

Power supply |

±15V/5A |

Signal protocol |

XY2-100 |

Working temperature |

-10 to 55° |

Storage temperature |

-10 to 60° |

External dimension LWH (mm) |

346x158x380 |

|

|