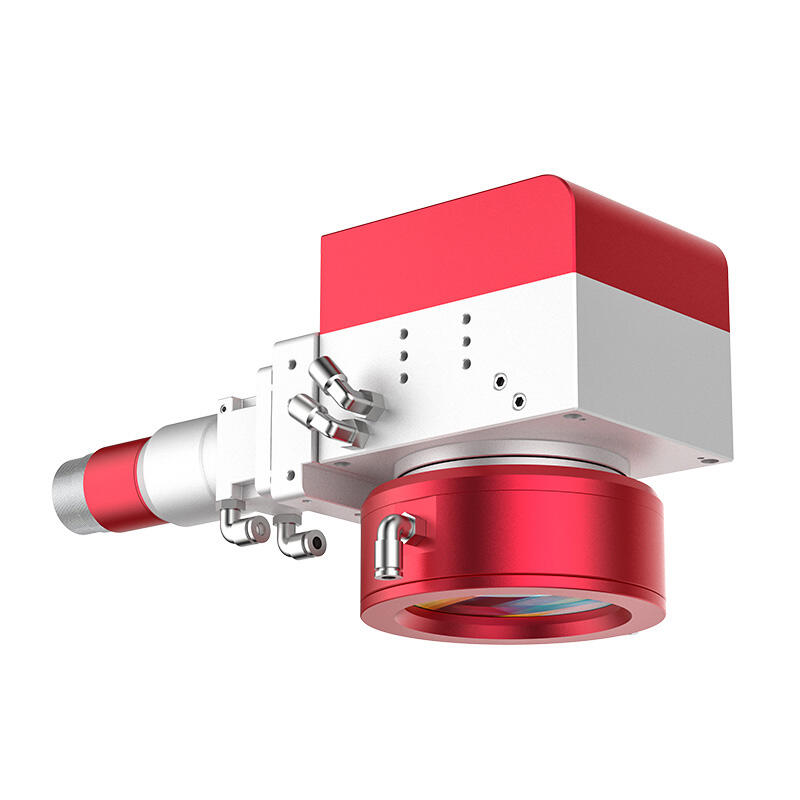

3D additive manufacturing galvos are mainly used in various types of laser 3D additive manufacturing, such as complex aerospace components, customized medical implants, automotive rapid prototyping and functional parts, and conformal cooling channels for industrial molds. They play a key role in typical application scenarios such as selective laser sintering (SLS), selective laser melting (SLM), and stereo lithography (SLA), helping to achieve high-precision, complex structure 3D object components.

Product advantages

● High reliability

Adopting self-developed high-end grating/photoelectric galvo motors, each galvo has undergone rigorous environmental and performance tests and can maintain long-term stable operation under extreme conditions. It can be equipped with a real-time monitoring system to monitor the lens temperature and operating status in real time, realize closed-loop control, effectively prevent failures, and maximize the reliable operation of the equipment.

● High stability

Adopt multi-level anti-interference design and multi-level closed-loop control algorithm to effectively resist electromagnetic interference and mechanical vibration; Select high-grade optical materials, with precision coating process, minimize light loss and thermal distortion, and ensure stable and reliable beam quality; The body reaches IP6 dustproof standard and supports water cooling to ensure long-term stable operation of the galvo without fear of harsh environmental challenges.

● High precision

Adopt high-precision motor, with high-resolution encoder (grating 24-bit/photoelectric stepless), combined with advanced multi-level closed-loop control algorithm, support 16-bit/18-bit command input, achieve micron-level positioning accuracy and extremely low temperature drift characteristics, ensure that every detail is accurately presented, and bring excellent precision guarantee for additive manufacturing.

● High efficiency

Adopt high-response motor and high-speed driver, fast printing speed and high efficiency.

Product Parameters | |

Output |

QBH |

Input aperture |

20 mm |

Scan angle |

±0.35 rad |

Nonlinearity |

<0.5 mrad |

Tracking error time |

0.35 ms |

Repeatability (RMS) |

<2 urad |

Gain drift |

<25 ppm/K |

Zero drift |

<15urad/K |

Long-term drift over 8 hours(after 30 min warm-up) |

<0.1 mrad |

Scan speed |

8000mm/s |

Laser wavelength |

1064nm |

Power supply |

±15 VDC Max.5A |

Operating temperature |

25±10(℃) |

Signal protocol |

ZL2-100/XY2-100 |

Collimating lens |

F100/F120 optional |

Focusing lens |

F254/F330/F420 |

|

|