Selecting the optimal laser galvo system for industrial applications requires careful consideration of multiple technical and operational factors. Modern manufacturing environments demand precise beam positioning, exceptional speed, and reliable performance across diverse material processing tasks. A properly configured laser galvo system serves as the cornerstone of efficient laser marking, engraving, cutting, and welding operations. Understanding the critical selection criteria ensures maximum productivity and long-term operational success in your specific manufacturing environment.

The scanning speed capabilities of a laser galvo system directly impact production throughput and operational efficiency. High-performance galvanometer scanners typically achieve speeds exceeding 7000mm/s while maintaining positioning accuracy within ±10 micrometers. These specifications prove crucial for applications requiring rapid processing cycles without compromising precision. Advanced servo control algorithms ensure consistent performance across varying load conditions and environmental factors.

Positioning accuracy becomes particularly important in applications involving fine detail work, microelectronics processing, and precision marking requirements. The repeatability specification indicates the system's ability to return to identical positions consistently over extended operating periods. Professional-grade laser galvo system configurations incorporate closed-loop feedback mechanisms that continuously monitor and correct positioning errors in real-time.

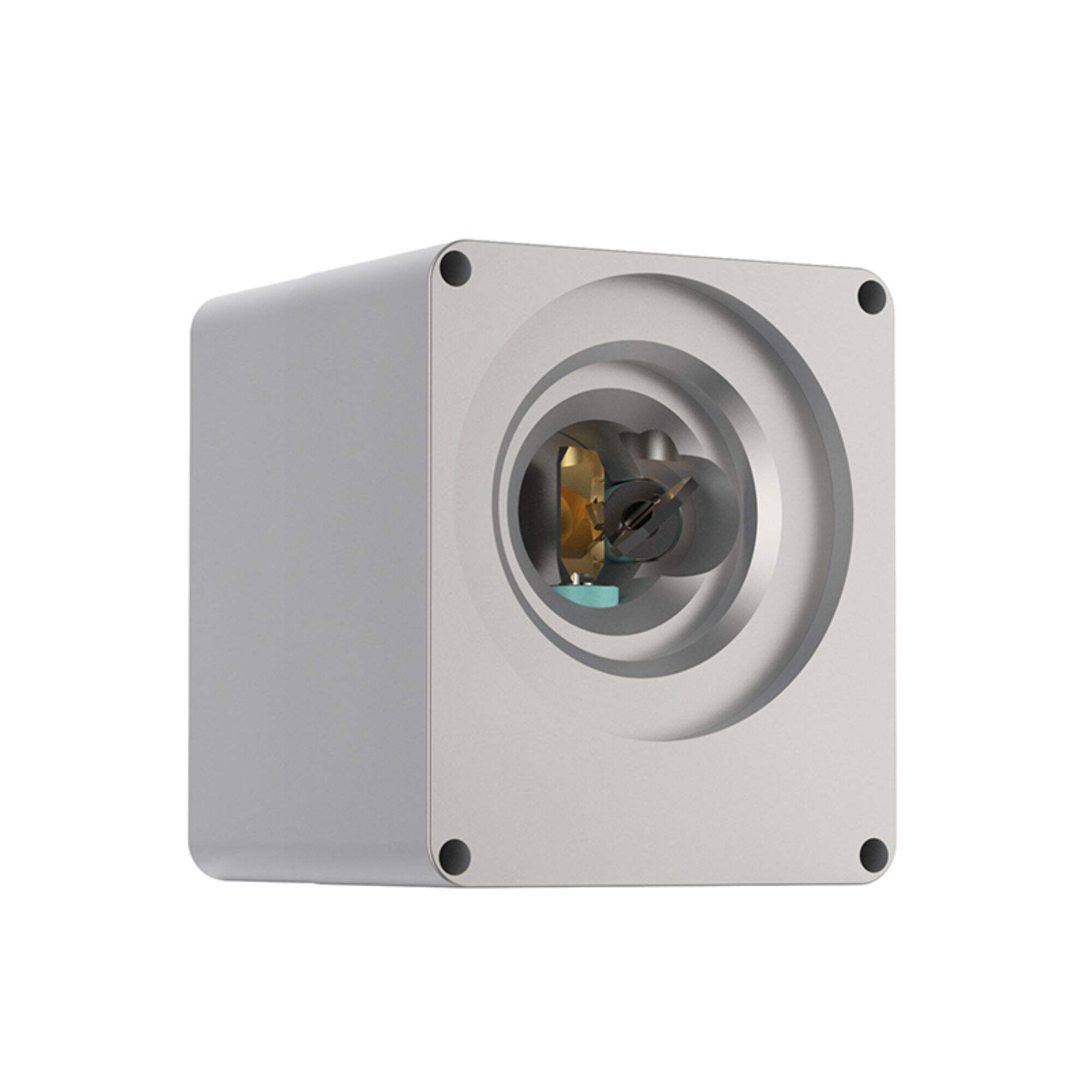

The aperture diameter of galvanometer mirrors determines the maximum working field size and influences beam quality characteristics. Larger apertures accommodate wider scanning areas but may introduce additional inertial effects that impact acceleration capabilities. Standard aperture sizes range from 10mm for high-speed applications to 25mm for large-format processing requirements. The relationship between aperture size and working field dimensions must align with specific application needs.

Working field dimensions establish the maximum processing area achievable with a single laser galvo system setup. Typical configurations support fields ranging from 70mm×70mm for precision work to 300mm×300mm for large-format applications. The lens focal length selection directly affects both working field size and feature resolution capabilities. Longer focal lengths increase working distance but reduce marking resolution, requiring careful optimization based on application requirements.

Different materials exhibit varying responses to laser processing, influencing the optimal laser galvo system configuration selection. Metals typically require higher power densities and specific wavelength characteristics for effective processing. Polymers and organic materials often respond well to shorter wavelengths and lower power settings. The thermal properties of target materials affect heat-affected zone dimensions and processing quality outcomes.

Surface preparation requirements and coating considerations impact laser interaction efficiency and processing results. Reflective materials may necessitate specialized wavelength selection or surface treatment protocols. The laser galvo system must accommodate these material-specific requirements through appropriate power control and beam delivery configurations.

Production volume requirements significantly influence the appropriate laser galvo system selection for manufacturing environments. High-volume applications benefit from systems optimized for maximum scanning speeds and minimal processing times per part. Continuous operation capabilities and thermal management systems become critical factors for sustained production environments. Duty cycle specifications indicate the system's ability to maintain performance under extended operating conditions.

Throughput optimization involves balancing processing speed, quality requirements, and system reliability considerations. Advanced laser galvo system designs incorporate predictive algorithms that optimize scanning patterns and reduce non-productive motion time. Integration with automated material handling systems enables seamless production line integration and maximized operational efficiency.

The compatibility between laser sources and galvanometer scanning systems affects overall system performance and operational flexibility. Fiber lasers, CO2 lasers, and diode-pumped solid-state lasers each present unique integration requirements and performance characteristics. Beam delivery optics must accommodate specific wavelength ranges and power density requirements of the selected laser source. Proper impedance matching ensures optimal energy transfer and beam quality maintenance.

Power handling capabilities of the laser galvo system must exceed the maximum output specifications of the integrated laser source. Thermal management systems prevent performance degradation under high-power operating conditions. Advanced systems incorporate real-time power monitoring and automatic protection mechanisms that safeguard components from damage due to excessive energy levels.

Modern manufacturing environments require seamless integration between laser galvo system controllers and existing production management systems. Industry-standard communication protocols enable real-time data exchange and remote monitoring capabilities. Programmable logic controller compatibility ensures straightforward integration with automated production lines and quality control systems.

Software compatibility affects operational flexibility and user productivity in laser galvo system applications. Advanced control software packages provide intuitive interfaces for job setup, parameter optimization, and production monitoring. Database connectivity enables traceability requirements and quality documentation in regulated industries. The control system architecture should accommodate future expansion and feature enhancement requirements.

Environmental factors significantly impact laser galvo system performance and longevity in industrial applications. Temperature stability requirements ensure consistent positioning accuracy and prevent thermal drift effects. Humidity control prevents condensation formation on optical components and maintains beam quality characteristics. Vibration isolation systems protect sensitive galvanometer mechanisms from external disturbances that could affect positioning accuracy.

Cleanroom compatibility becomes essential for applications in semiconductor, medical device, and precision manufacturing environments. Sealed enclosure designs prevent contamination of optical components while maintaining thermal management capabilities. Air filtration systems remove particulates that could interfere with laser beam propagation and processing quality. The laser galvo system enclosure rating must meet specific environmental classification requirements for the intended operating environment.

Preventive maintenance requirements affect total cost of ownership and operational availability for laser galvo system installations. Component accessibility influences maintenance time requirements and technician skill level needs. Diagnostic capabilities enable predictive maintenance strategies that minimize unexpected downtime and extend component service life. Calibration procedures must accommodate production schedule requirements without excessive interruption.

Service support availability and response time capabilities impact production continuity in critical manufacturing applications. Local service infrastructure and spare parts availability affect maintenance cost structures and downtime risks. Training requirements for operational and maintenance personnel influence implementation timelines and ongoing operational costs. The laser galvo system manufacturer's support network should align with geographic location and service level requirements.

The initial capital investment for a laser galvo system encompasses equipment costs, installation requirements, and integration expenses. High-performance systems command premium pricing but deliver superior throughput and accuracy capabilities. Cost-benefit analysis must consider production volume projections, quality improvements, and labor reduction potential. Financing options and lease arrangements may improve cash flow management for capital equipment acquisitions.

Installation costs vary based on facility preparation requirements, utility connections, and safety system integration needs. Electrical power requirements may necessitate facility upgrades for high-performance laser galvo system installations. Ventilation and fume extraction systems add to overall project costs but ensure safe operating conditions. Professional installation services reduce commissioning time and ensure optimal system performance from startup.

Operating costs include energy consumption, consumable materials, maintenance expenses, and labor requirements. Energy-efficient laser galvo system designs reduce utility costs while maintaining performance specifications. Automated operation capabilities minimize labor requirements and reduce operational costs per processed part. Predictive maintenance strategies optimize component replacement timing and reduce emergency service expenses.

Quality improvement benefits translate to reduced rework costs, improved customer satisfaction, and enhanced market competitiveness. Consistent processing results minimize material waste and improve overall production efficiency. Advanced laser galvo system capabilities enable new product offerings and market opportunities that justify investment costs through revenue enhancement rather than cost reduction alone.

High-performance laser galvo system configurations typically achieve scanning speeds between 5000-8000mm/s while maintaining positioning accuracy within ±5-10 micrometers. The actual achievable speed depends on factors such as mark complexity, required accuracy, and material characteristics. Simple geometric patterns enable maximum speed operation, while intricate designs may require reduced speeds to maintain quality standards.

Aperture size selection depends on your required working field dimensions and processing speed requirements. Smaller apertures like 10mm enable higher acceleration and deceleration rates but limit maximum working field size. Larger apertures up to 25mm accommodate bigger working fields but may reduce maximum achievable speeds due to increased mirror inertia in the laser galvo system design.

Regular maintenance includes optical component cleaning, calibration verification, and mechanical component inspection. Most laser galvo system installations require quarterly calibration checks and annual comprehensive servicing. Daily operational checks should include beam alignment verification and positioning accuracy testing to identify potential issues before they affect production quality.

Many laser galvo system components can be upgraded independently to improve performance characteristics. Scanner head replacements enable speed and accuracy improvements, while controller upgrades may add advanced features and connectivity options. However, compatibility between components must be verified to ensure optimal integration and performance in upgraded configurations.

Hot News

Hot News2026-01-11

2026-01-07

2026-01-01

2025-12-03

2025-12-11

2025-12-19