Modern manufacturing and engraving industries have witnessed remarkable transformations through advanced beam steering solutions. Among these innovations, laser galvo technology stands as a cornerstone for achieving precision, speed, and versatility in complex marking applications. This sophisticated system utilizes high-speed mirror movements to redirect laser beams with exceptional accuracy, enabling manufacturers to complete intricate engraving tasks that were previously impossible or economically unfeasible.

The integration of galvanometer-based laser systems has revolutionized how industries approach marking, engraving, and cutting operations. These systems offer unparalleled flexibility in handling diverse materials while maintaining consistent quality across high-volume production runs. Understanding the fundamental principles and applications of laser galvo technology provides valuable insights into why this innovation has become indispensable for contemporary manufacturing processes.

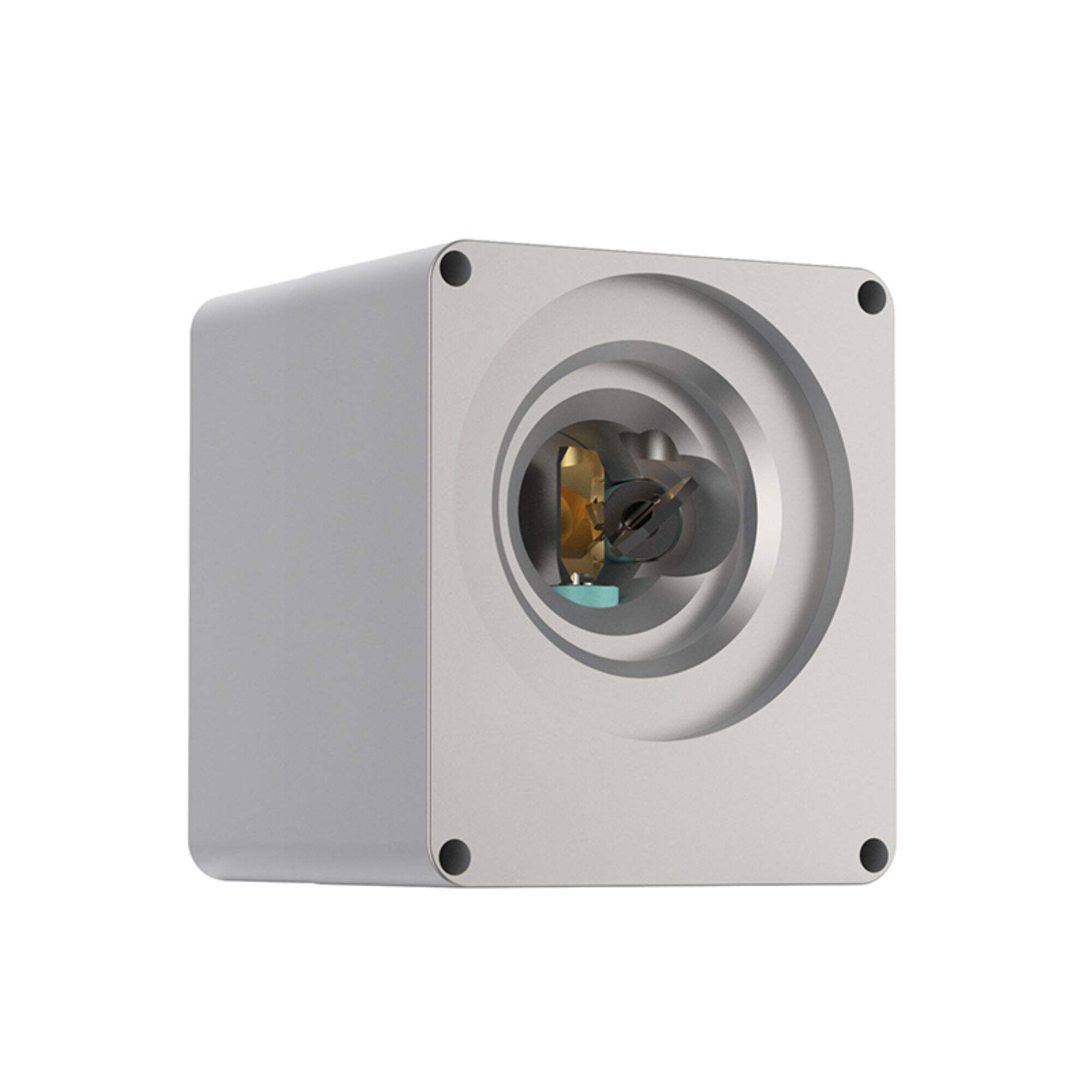

At the heart of laser galvo technology lies the sophisticated galvanometer scanning system, which employs precision-engineered mirrors mounted on high-speed servo motors. These galvanometers can achieve positioning accuracies within micrometers while maintaining exceptional repeatability across millions of operational cycles. The mirrors redirect laser beams through precise angular movements, creating complex patterns and designs with remarkable speed and accuracy.

The servo control systems governing these galvanometers utilize advanced feedback mechanisms to ensure consistent performance even under demanding operating conditions. Position encoders continuously monitor mirror angles, enabling real-time corrections that maintain beam positioning accuracy throughout extended production runs. This level of precision control makes laser galvo technology particularly valuable for applications requiring tight tolerances and consistent quality standards.

Modern galvanometer systems incorporate sophisticated beam path optimization algorithms that minimize travel distances while maximizing processing efficiency. These algorithms analyze engraving patterns and automatically determine optimal scanning sequences, reducing cycle times and improving overall productivity. The dynamic nature of laser galvo technology allows for seamless transitions between different marking patterns without mechanical repositioning.

Dynamic focusing capabilities further enhance the versatility of these systems by automatically adjusting beam convergence based on workpiece geometry and material characteristics. This adaptive focusing ensures consistent energy density across varying surface topographies, maintaining engraving quality regardless of substrate variations. The combination of precise beam steering and dynamic focusing positions laser galvo technology as an ideal solution for complex three-dimensional engraving applications.

One of the most significant advantages of laser galvo technology is its exceptional processing speed, which stems from the lightweight construction and minimal inertia of galvanometer mirrors. Unlike mechanical positioning systems, galvanometers can achieve positioning speeds exceeding several meters per second while maintaining sub-micron accuracy. This rapid positioning capability translates directly into higher throughput and improved production efficiency.

The acceleration and deceleration characteristics of modern galvanometer systems enable smooth motion profiles that minimize settling times and reduce mechanical stress on system components. Advanced motion control algorithms optimize acceleration curves to balance speed with precision, ensuring that laser galvo technology delivers consistent results even at maximum operating speeds. This optimization becomes particularly important in applications requiring frequent direction changes or complex geometric patterns.

The contactless nature of galvanometer operation eliminates many wear mechanisms associated with traditional mechanical positioning systems, resulting in extended operational lifespans and reduced maintenance requirements. Laser galvo technology systems can operate continuously for thousands of hours with minimal degradation in performance, making them ideal for high-volume manufacturing environments where downtime must be minimized.

Thermal management systems integrated into modern galvanometer designs ensure stable operation even under demanding thermal conditions. Heat dissipation strategies, including active cooling and thermal compensation algorithms, maintain consistent positioning accuracy throughout extended operating periods. This reliability factor has made laser galvo technology the preferred choice for mission-critical applications where consistent performance is essential.

The flexibility inherent in laser galvo technology enables effective processing of diverse material types, from delicate organic substrates to robust metallic alloys. Parameter optimization capabilities allow operators to adjust laser power, scanning speed, and pulse characteristics to match specific material requirements. This adaptability eliminates the need for multiple specialized systems, reducing capital investment and operational complexity.

Advanced materials processing techniques, including layer removal, surface texturing, and selective heating, become readily achievable through precise control of laser galvo technology parameters. The ability to modulate laser characteristics in real-time enables sophisticated processing strategies that would be impossible with fixed-beam systems. This versatility extends the application range of galvanometer-based systems into emerging markets and novel manufacturing processes.

Three-dimensional surface processing capabilities represent another significant advantage of laser galvo technology, as these systems can maintain focus and positioning accuracy across curved and irregular surfaces. Height sensing systems integrated with galvanometer controls enable automatic surface following, ensuring consistent processing quality regardless of workpiece geometry variations.

The programmable nature of galvanometer systems facilitates complex pattern generation and modification without hardware changes. Operators can implement sophisticated designs, including variable-depth engraving, gradient effects, and multi-layer structures, through software control alone. This programming flexibility makes laser galvo technology particularly valuable for custom manufacturing and prototyping applications where design changes are frequent.

The precision capabilities of modern laser galvo technology systems routinely achieve positioning accuracies measured in micrometers, enabling the production of extremely fine features and detailed patterns. Closed-loop feedback control systems continuously monitor and correct mirror positions, maintaining this level of accuracy throughout extended operating periods. Environmental compensation algorithms further enhance precision by accounting for temperature variations and mechanical drift.

Calibration procedures for galvanometer systems have evolved to include advanced characterization techniques that map system performance across the entire working field. These calibrations account for optical distortions, mechanical tolerances, and thermal effects, ensuring that laser galvo technology delivers consistent accuracy regardless of beam position within the processing area.

Statistical process control capabilities integrated into laser galvo technology systems enable real-time monitoring of engraving quality and consistency. These systems can detect variations in processing parameters and automatically adjust settings to maintain specified tolerances. Quality assurance features, including in-process verification and automated inspection, ensure that production standards are maintained throughout manufacturing runs.

The deterministic nature of galvanometer positioning eliminates many sources of variability associated with mechanical positioning systems. Laser galvo technology systems can reproduce identical patterns with exceptional consistency, making them ideal for applications where part-to-part uniformity is critical. This repeatability extends beyond simple positioning to include complex processing parameters such as laser power distribution and scanning velocity profiles.

The operational efficiency of laser galvo technology translates directly into reduced per-part processing costs through increased throughput and minimized material waste. Energy consumption optimization features ensure that laser power is utilized efficiently, reducing operational expenses while maintaining processing quality. Automated operation capabilities further reduce labor costs by minimizing the need for skilled operators during routine production runs.

Maintenance costs for galvanometer-based systems remain low due to the minimal number of moving parts and the absence of contact-based wear mechanisms. Predictive maintenance algorithms can identify potential issues before they impact production, enabling scheduled maintenance during planned downtime periods. This proactive approach to maintenance reduces unexpected failures and extends system operational life.

The modular design of modern laser galvo technology systems enables easy expansion and upgrade paths as production requirements evolve. Additional processing heads, enhanced control systems, and improved laser sources can be integrated into existing installations without complete system replacement. This scalability protects initial investments while enabling adaptation to changing market demands.

Software-based functionality updates ensure that laser galvo technology systems can incorporate new processing techniques and optimization algorithms without hardware modifications. This upgrade capability extends system useful life and maintains competitiveness in rapidly evolving manufacturing environments. The combination of hardware durability and software flexibility provides exceptional long-term value for manufacturing investments.

Electronics manufacturing has embraced laser galvo technology for its ability to create precise circuit patterns, component markings, and quality identification codes on sensitive substrates. The contactless nature of laser processing eliminates mechanical stress on delicate components while enabling processing speeds that match high-volume production requirements. Semiconductor applications particularly benefit from the precision and repeatability characteristics of galvanometer systems.

Advanced packaging techniques in the electronics industry rely heavily on laser galvo technology for creating complex interconnection patterns and fine-pitch features. The ability to process multiple layers and create three-dimensional structures has opened new possibilities for miniaturization and performance enhancement in electronic devices. Quality control applications, including defect identification and traceability marking, further expand the utility of these systems in electronics manufacturing.

Automotive manufacturers utilize laser galvo technology for component identification, safety marking, and decorative applications across diverse material types. The durability and precision of galvanometer systems make them suitable for marking critical components that must maintain identification throughout extended service lives. Engine components, transmission parts, and safety systems all benefit from the permanent, high-contrast markings achievable with laser processing.

Aerospace applications demand the highest levels of precision and reliability, making laser galvo technology an ideal choice for component processing and identification. Traceability requirements in aerospace manufacturing necessitate permanent, machine-readable markings that can withstand extreme environmental conditions. The precision capabilities of galvanometer systems enable marking of critical information on components with minimal impact on structural integrity or performance characteristics.

Laser galvo technology achieves superior speed through its lightweight mirror-based positioning system, which eliminates the inertia associated with heavy mechanical components. The galvanometers can achieve positioning speeds exceeding several meters per second while maintaining micron-level accuracy. Additionally, the contactless nature of the process eliminates tool wear and the need for frequent tool changes, enabling continuous operation at optimal speeds.

Modern laser galvo technology systems routinely achieve positioning accuracies within micrometers, significantly outperforming traditional mechanical positioning systems. The closed-loop feedback control and advanced servo systems enable consistent repeatability across millions of operational cycles. Environmental compensation algorithms further enhance precision by automatically correcting for temperature variations and mechanical drift throughout extended operating periods.

Laser galvo technology systems require minimal maintenance due to their contactless operation and robust design. Routine maintenance typically involves periodic cleaning of optical components and verification of calibration settings. The absence of mechanical wear components eliminates many traditional maintenance requirements, while predictive monitoring systems can identify potential issues before they impact production quality or efficiency.

Yes, modern laser galvo technology systems excel at three-dimensional processing through integrated height sensing and dynamic focusing capabilities. These systems can automatically adjust focus and positioning to follow complex surface geometries while maintaining consistent processing quality. The combination of precise beam steering and adaptive focusing enables sophisticated three-dimensional engraving applications that would be challenging or impossible with fixed-beam systems.

Hot News

Hot News2026-01-11

2026-01-07

2026-01-01

2025-12-03

2025-12-11

2025-12-19